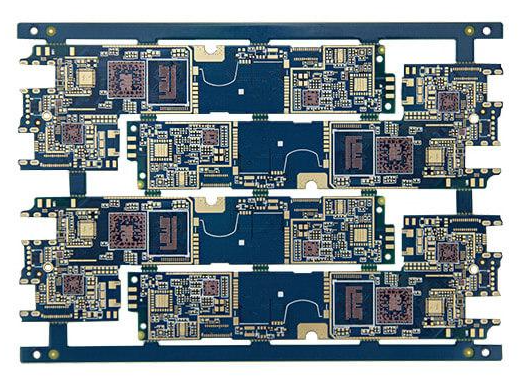

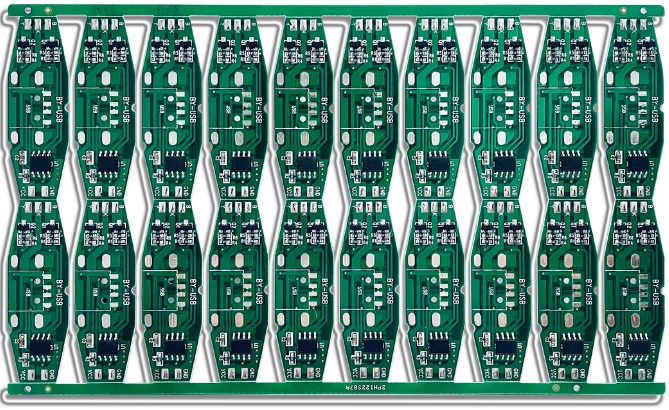

multi-layer PCB

High-end design,

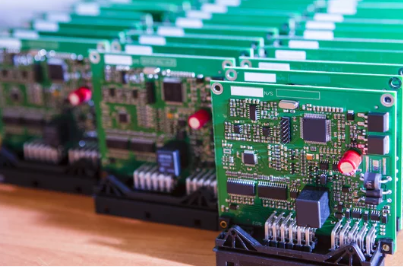

Read MoreHXPCB is a supplier engaged in the PCB industry. We provide one-stop production and assembly services for ordinary PCB, double-sided PCB, multi-layer PCB, aluminum PCB, rigid-flex PCB, HDI PCB, drone PCB and high-frequency PCB. Our production equipment and technical team enable us to have more favorable prices for our high-quality products.

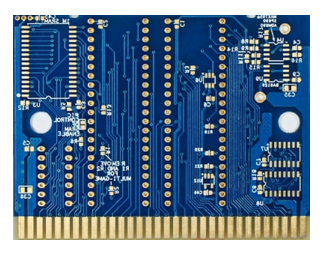

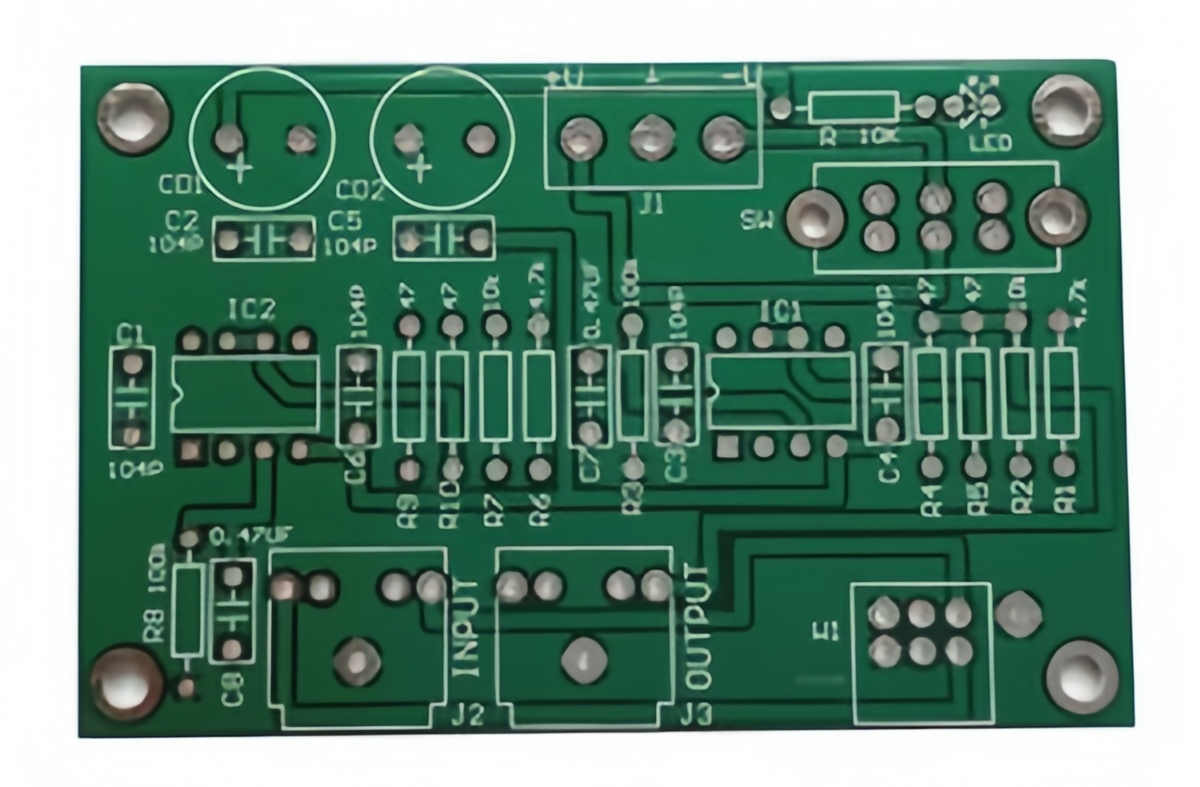

A prototype PCB is an initial or experimental version of a printed circuit board (PCB) designed to test and validate the functionality of a new design before mass production. It is used to verify the design, functionality, and performance of the circuit, identify any issues or improvements, and ensure that the final product will meet the required specifications. Prototype PCBs are typically produced in small quantities and are essential for engineers to test the design’s electrical, mechanical, and thermal performance in real-world conditions.

We provide high-quality prototype PCB manufacturing services to accelerate your product development process. Whether you are developing consumer electronics, medical applications, or complex high-frequency circuits, we can provide fast-delivery prototypes that meet your precise specifications. Our experienced engineering team will support you every step of the way, from design optimization to material selection, ensuring that your prototypes are tested for reliability and performance. We offer flexible design options, including multi-layer boards, rigid-flex boards, and high-speed PCBs, to meet a variety of application needs. Our competitive pricing and commitment to quality ensure that you get the best value without compromising performance.

Prototype PCBs allow you to test your design before full production, identifying issues such as design flaws, component placement problems, or manufacturing challenges. Addressing these issues early on saves time and money.

Confirming that the design works as expected and meets the required specifications helps ensure that the final product will function properly in the actual application.

Prototyping allows for an iterative design approach, where by testing and refining the prototype, engineers can make incremental changes and improvements that lead to a more optimized and reliable final product.

Prototyping tests and validates designs in a cost-effective way before investing in large-scale production. The risk of errors that could occur during full-scale manufacturing is greatly reduced.

Prototype PCBs offer the flexibility to try different designs, materials, and components. This allows engineers to explore the best solution for a specific application, making it easier to customize and optimize the product.

Using prototype PCBs allows engineers to quickly identify and resolve issues, which speeds up the product development process.

Prototype PCBs allow engineers to test and validate circuit designs before committing to mass production. They help ensure that designs function as expected under real-world conditions.

Prototype PCBs provide the opportunity to evaluate the reliability and performance of a design under a variety of conditions, allowing necessary adjustments to be made before full production.

Customization: Prototype PCBs offer the flexibility to try different materials, layouts, and component placements, helping engineers create highly optimized designs.

Risk Reduction: By testing prototypes, engineers can identify potential risks and challenges early in the process, reducing the likelihood of failures in mass production.

Fast Delivery Time

We understand the importance of speed in product development. By optimizing our processes, we ensure fast delivery of prototype PCBs, helping you accelerate your design cycle and reduce time to market.

High Quality Standards

We use advanced manufacturing techniques and premium materials to produce high-quality prototype PCBs. Each board is rigorously tested to ensure its reliability, performance, and functionality.

Professional Engineering Support

Our engineering team provides tailored support, from design optimization to troubleshooting, to ensure your prototype PCBs meet the highest performance and manufacturability standards.

Flexible Design Capabilities

We offer a variety of design options, including multi-layer boards, rigid-flex boards, high-frequency PCBs, and custom PCB solutions, making us an ideal partner for complex and innovative projects.

Competitive Solutions

We offer competitive pricing without sacrificing quality. Our cost-effective services ensure that you don’t overspend when testing and validating your designs.

Comprehensive Testing

We conduct comprehensive testing on all prototypes to ensure electrical performance, signal integrity, and mechanical stress testing to ensure the success of the final product.

Customized Services

We work closely with you to understand your unique needs and provide customized solutions that meet the specific requirements of your project. Whether it’s small batches or more complex designs, we’ve got your back.

New Product Development: Prototype PCBs are critical in the development of new electronic products, such as wearables, consumer electronics, automotive systems, and medical devices. Engineers use prototyping to test and refine designs before mass production.

Testing and Validation: Prototypes play an important role in testing and validating circuit functionality, signal integrity, and power distribution, especially in high-performance applications such as aerospace, military electronics, and communications, ensuring the reliability of designs under real-world conditions.

Embedded Systems: Prototype PCBs are used to develop and test embedded systems, such as microcontrollers, sensors, and IoT devices, ensuring the correct operation of each component before mass production.

R&D and Innovation: R&D engineers use prototype PCBs to experiment with new materials, components, and layouts. Prototype PCBs help innovate and test new concepts before mass production.

High-Frequency and High-Speed Circuits: Prototyping helps develop and test high-frequency and high-speed circuits, such as those used in radio frequency (RF) communication systems, satellite communications, and radar technology.

Customization: Prototype PCBs allow PCB designs to be customized to specific application needs. This flexibility is particularly important in specialized markets such as medical, automotive, and industrial equipment.

New Product Development: Prototype PCBs are critical in the development of new electronic products, such as wearables, consumer electronics, automotive systems, and medical devices. Engineers use prototyping to test and refine designs before mass production.

Testing and Validation: Prototypes play an important role in testing and validating circuit functionality, signal integrity, and power distribution, especially in high-performance applications such as aerospace, military electronics, and communications, ensuring the reliability of designs under real-world conditions.

Embedded Systems: Prototype PCBs are used to develop and test embedded systems, such as microcontrollers, sensors, and IoT devices, ensuring the correct operation of each component before mass production.

R&D and Innovation: R&D engineers use prototype PCBs to experiment with new materials, components, and layouts. Prototype PCBs help innovate and test new concepts before mass production.

High-Frequency and High-Speed Circuits: Prototyping helps develop and test high-frequency and high-speed circuits, such as those used in radio frequency (RF) communication systems, satellite communications, and radar technology.

Customization: Prototype PCBs allow PCB designs to be customized to specific application needs. This flexibility is particularly important in specialized markets such as medical, automotive, and industrial equipment.

A prototype PCB is a test version of a printed circuit board (PCB) used to validate the design and functionality of an electronic circuit before mass production. It helps identify issues such as signal integrity, component placement, and electrical performance.

The turnaround time for a prototype PCB can vary, but typically, it takes around 3 to 7 days for standard prototypes. This may vary depending on the complexity of the design and the required testing.

The cost depends on several factors, including the complexity of the design, number of layers, material used, and quantity. Generally, the cost for a prototype PCB ranges from $50 to $500 per board.

Yes, after testing and validating a prototype, you can use the same design for mass production, provided no significant changes are needed. However, some optimizations may be applied based on the testing results.

Prototype PCBs can include single-layer, multi-layer, rigid-flex, high-frequency, and flexible PCBs. The type depends on the specific application and the design requirements.

Yes, we specialize in high-frequency PCB prototyping, which is essential for applications such as wireless communication, radar, and high-speed data transmission.

Yes, we offer engineering support during the prototyping phase to help with design optimization, material selection, and troubleshooting to ensure your prototype meets performance and manufacturability standards.

Common tests include electrical testing, signal integrity analysis, mechanical stress tests, and thermal testing. These ensure that the PCB will perform reliably in real-world conditions.

Aluminum PCBs have high mechanical strength, able to withstand significant external pressure, making them suitable for high temperatures and harsh environments.

The materials used in prototype PCBs can include FR4 (for standard designs), Rogers, PTFE, and other specialized materials, depending on the specific performance needs of the project.