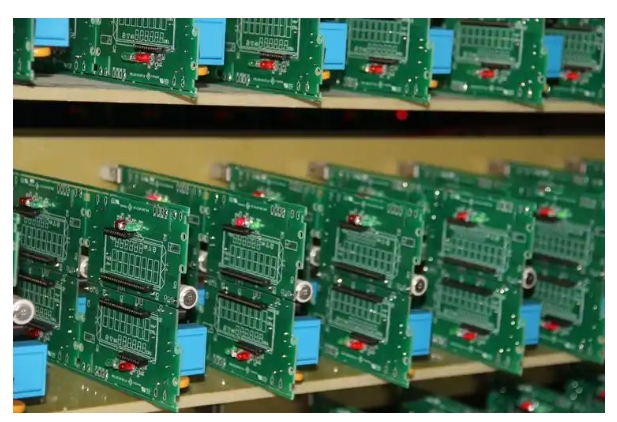

Smart Instrument PCB

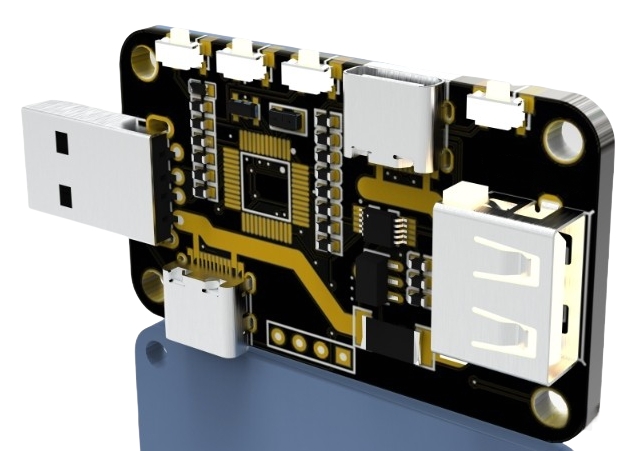

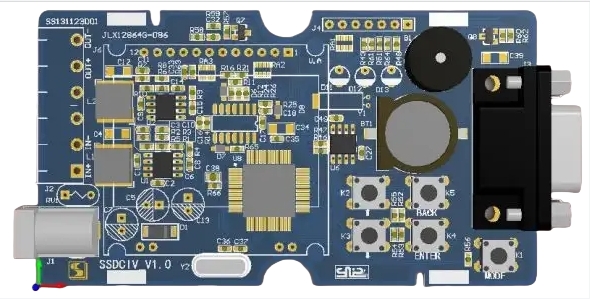

Smart Instrument PCB product display produced by HXPCB

HXPCB is a supplier engaged in the PCB industry, providing one-stop production and assembly services such as ordinary PCB, double-sided PCB, multi-layer PCB, aluminum substrate, rigid-flex PCB, HDI PCB, high-frequency PCB and other PCB products. It has strong production equipment and technical team to provide customers with high-quality products, more favorable prices and more considerate services.

What is a Smart Instrument PCB?

Smart Instrument PCB (smart instrument printed circuit board) generally refers to a special printed circuit board used in modern smart instruments. These instruments are widely used in medical, industrial automation, consumer electronics and other fields, with advanced functions and intelligent features.

Smart Instrument PCB assembly

1.Smart Instrument PCB board production

PCB board is the core of smart electronic meter. The production includes circuit design, proofing, cutting, copper plating, copper plating treatment, coating and other processes to ensure stable and reliable circuit.

2.Component procurement

It is necessary to purchase a variety of electronic components, such as resistors, capacitors, integrated circuits (ICs), etc., to ensure that all components meet quality standards.

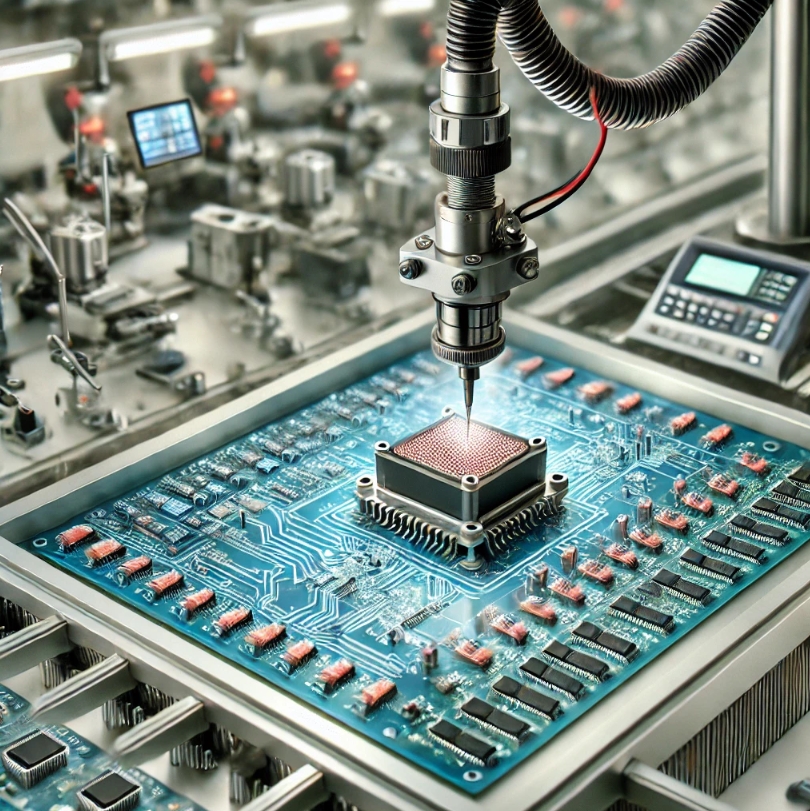

3.SMT mounting

SMT (surface mount technology) mounts electronic components on PCB boards quickly and accurately to improve production efficiency and quality.

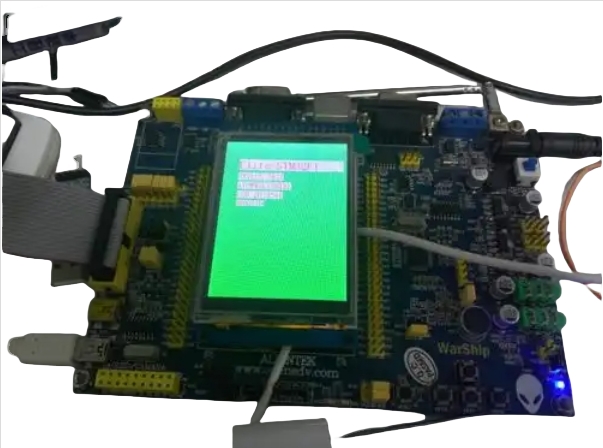

4.Program burning

In smart meters, MCU programs, DSP algorithms, LCD display drivers and other software need to be burned in advance to ensure complete functions.

5.Welding and welding

Each component is welded, usually using wave soldering technology to improve connection reliability.

6.Testing

Perform circuit board, sensor and whole machine performance tests to ensure that the product meets the accuracy and stability requirements.

7.Packaging and shipment

Finally complete product packaging, labeling, and delivery to sales channels.

HXPCB provides production and assembly services for Smart Instrument PCB

With its outstanding technical advantages, precision technology and comprehensive services, HXPCB provides high-quality, low-power and reliable PCB integration solutions for smart electronic watches.

HXPCB has large-scale production capabilities and can ensure stable mass production and fast delivery. We are committed to helping customers choose HXPCB. You will have a pleasant experience that integrates technology, service and price.

Our manufacturing advantages in Smart Instrument PCB

1.Customized services to meet diverse needs

HXPCB provides a full range of customized services. We provide customized solutions according to customer needs to help customers create smart meter products that meet market demand.

2.Advanced production technology and equipment

Ensure that each PCB has excellent stability and high performance. Our manufacturing process strictly follows international quality standards, from the selection of raw materials to every process, we strive for excellence.

3.Precise manufacturing, accurate measurement

HXPCB uses manufacturing technology to ensure that the PCB circuit board of the smart meter reaches 4mil width/density, ensuring the accuracy of power measurement. We support multi-layer PCB design, which can meet the needs of smart meters for complex function integration.

4.Competitive prices in the market

We have advanced manufacturing equipment and production processes, and there are processes from PCB production to finished product assembly, making our quotes more affordable.

5.Quality service

We show the spirit of high-quality service to every customer, leaving all the unpleasant factors to us, and giving customers a satisfied smile.