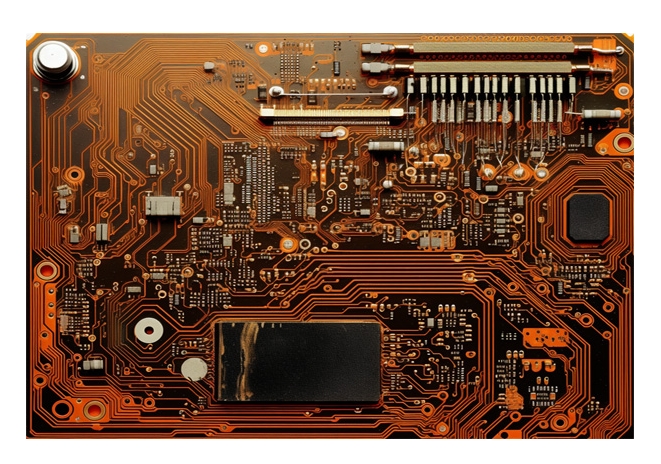

multi-layer PCB

High-end design, multi-layer PCB internal structure and experience sharing

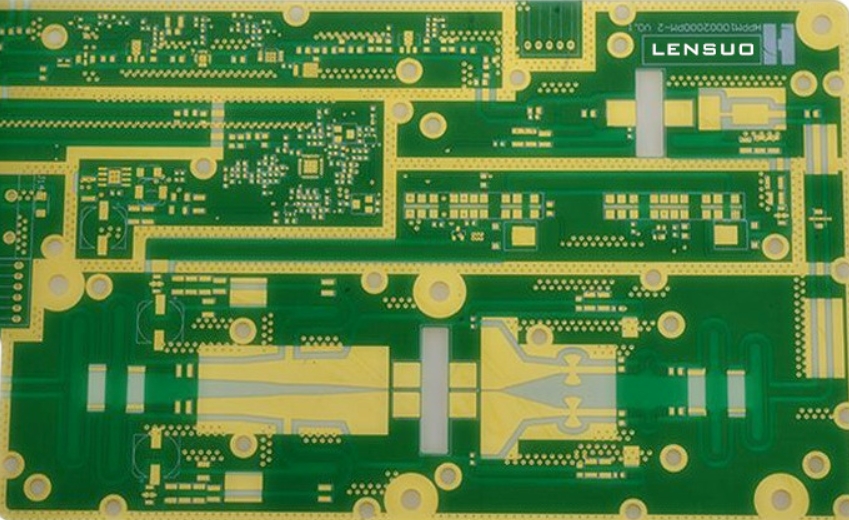

Read MoreIn the field of industrial electronic products, HXPCB provides customers with the most optimized solutions through precise processes and professional technologies. With more than ten years of rich experience and a deep understanding of industry dynamics, we focus on providing customers with high-quality and reliable industrial control PCB products and services. By adopting advanced manufacturing technology and strict quality management systems, we are able to meet the needs of the industrial field for circuit boards.

HXPCB focuses on manufacturing industrial PCBs that can withstand extreme temperatures, moisture reduction, shock and vibration. We provide a full range of customized products including rigid PCBs, flexible PCBs and rigid-flexible PCBs for various industrial scenarios.

HXPCB has a deep understanding of the customized needs and challenges of OEM customers in the industrial field. We have a group of experienced engineers and technical teams who can work closely with customers to provide service support from concept to mass production. By adopting cutting-edge production equipment and advanced manufacturing processes, we ensure the delivery of products that meet or even exceed customer expectations. Contact HXPCB to customize your exclusive industrial electronic solutions.。

1. High reliability and durability

We have a complete manufacturing system that strictly controls every detail and selects the right materials to produce reliable and durable printed circuit boards

2. Strict material selection

Use high heat-resistant substrates to withstand high temperature and high current requirements. Use water-absorbing materials to reduce the impact of moisture on performance. Use special materials such as PTFE or metal substrates to meet special industrial applications.

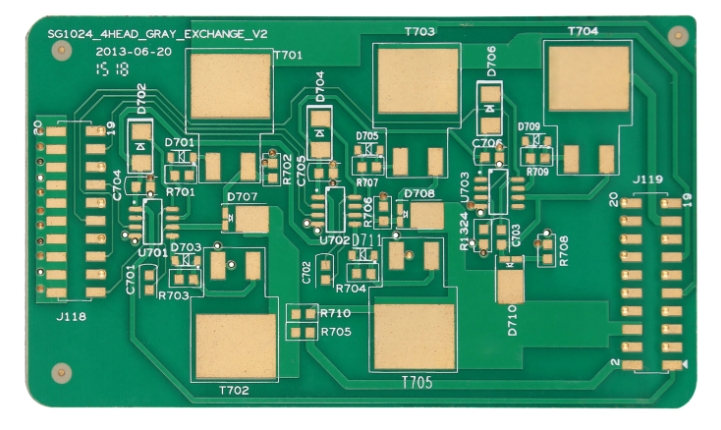

3. High-precision processing

Strict tolerance control: achieve extremely high performance on key indicators such as wiring, line width and line spacing to meet the requirements of complex circuit design. Precision surface treatment and impedance control: optimize welding performance, improve conductivity, and improve oxidation resistance.

4. High quality and certification standards

Our industrial control PCBs meet various international certification standards

IPC-A-610: Acceptance criteria for electronic components.

ISO 9001: Quality management system.

UL certification: ensure PCB reinforcement and safety performance.

RoHS/REACH: comply with environmental regulations and reduce the use of pollutants.

5. Large-scale production and flexible delivery

Able to meet the needs of industrial customers for low, medium and large-scale production.

Provide fast delivery service to meet urgent production or equipment maintenance needs.

6. High-quality partners and service spirit

Choosing HXPCB is choosing an excellent and powerful partner. We are your most loyal backing. Although we are partners, you are still our God because you are also our customer. Our purpose is: do our best to satisfy you.

| Category | Technical Parameters |

|---|---|

| Layers & Dimensions | Maximum 64 |

| Board thickness: 0.2mm to 6.0mm | |

| Dimensions: 600mm x 1200mm | |

| Conductivity | 1 oz — 12 oz (3 T) |

| Precision | Minimum: 3 mil/3 mil (0.075mm) |

| Drilling tolerance: ±0.05mm | |

| Minimum drill size: 0.1mm (4 mil) | |

| Surface Finishes | ENIG (1-5μm), Immersion Silver/Tin, OSP, Hard Gold (0.5-1.5μm) |

| Impedance & High-Frequency | Impedance control: ±5% |

| High-frequency materials: PTFE, Rogers (e.g., RO4350B) | |

| Frequency range: 3GHz — 60GHz | |

| Environmental Durability | Operating temperature: -40°C to 150°C |

| Moisture resistance: <0.1% absorption | |

| Manufacturing Process | Multilayer lamination: bonding strength >1.5N/mm |

| Via copper thickness: 20-25μm | |

| Certifications | ISO 9001, IATF 16949, ISO 14001 |

| Applications | Automation, Power Electronics, Heavy Machinery, Monitoring Systems, Medical Equipment |

Whole machine assembly: including PCB assembly, harness connection, cable assembly and housing installation to achieve turnkey solutions. Production volume: supports small, medium and large batch production, and flexibly adapts to customer needs. Delivery capability: with rapid prototyping capabilities, the shortest delivery cycle reaches 3-7 working days.

(DFM/DFA) service: provide professional optimization suggestions in the design stage to improve the manufacturability, testability and efficient cost of products. Collaborative supply chain: Collaborate with multiple suppliers to ensure a stable supply of components and provide flexible inventory options. Technical support and after-sales service: Provide 24/7 online technical support to quickly respond to customer needs.

HXPCB strictly implements a comprehensive quality management process to ensure that products meet the high standards in the field of industrial control: Fully optical automated process detection: AOI (automatic inspection), SPI (solder paste inspection) cover each process. Functional testing (FCT): functional testing of each PCB component to ensure the normal operation of the circuit. X-Ray detection: used for the detection of precision solder joints (such as BGA) to ensure the correct welding quality. Environmental resistance testing: including high and low temperature, wet heat testing, to verify the reliability of products under extreme conditions.

High-end design, multi-layer PCB internal structure and experience sharing

Read More

PCB (Printed Circuit Board) inspection is an important part of ensuring product quality, performance and reliability.

Read More

Printed circuit boards (PCBs) play a vital role in connecting and supporting various electronic components. With

Read More