PCB Export: Navigating Global Standards, Advanced Manufacturing, and Material Science

How Physics-Driven Design and Compliance Shape International Success

Why Do 40% of PCB Exporters Fail Compliance Audits? A Technical Deep Dive

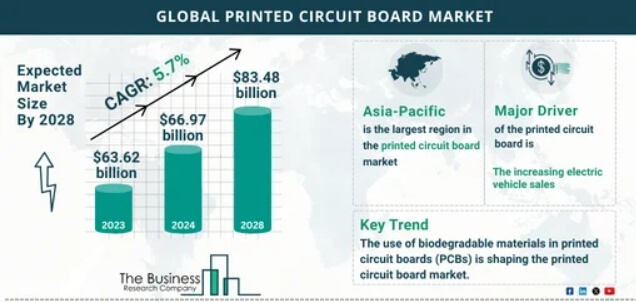

Global PCB exports reached $82.3 billion in 2023 (Prismark), yet supply chain disruptions and regulatory complexity plague manufacturers. From impedance mismatches to halogen-free material mandates, we dissect the multiphysics challenges defining modern PCB exports.

Interactive Global Export Heatmap:

Core Technical Challenges in PCB Export

1. Signal Integrity vs. Manufacturing Tolerances

Problem: Why do 5G mmWave PCBs (28 GHz) fail 30% more often in humid climates?

Physics & Microstructure:

- Moisture Absorption: FR-4’s dielectric constant (εr) shifts from 4.3 (dry) to 4.7 (85% RH), altering impedance (Z₀=√(L/C)).

- Data: 0.1 mm substrate swelling → ΔZ₀=±6% (IPC-4101 Class 3 limit: ±10%).

- Plating Voids: Electroless nickel immersion gold (ENIG) defects increase skin depth resistance (δ=√(2ρ/ωμ)) at 10+ GHz.

Export Compliance:

- IPC-6012 Class 3: Requires ≤5% impedance deviation and <2% void area in plating.

- Design Fix: Use Rogers 4350B (εr=3.48±0.05) for RF boards and vacuum lamination.

Case Study: Automotive Radar PCB (77 GHz)

- Failure: 12-layer HDI board warped due to CTE mismatch (Cu=17 ppm/°C vs. FR-4=14 ppm/°C).

- Solution: Switch to low-CTE polyimide (CTE=12 ppm/°C) and add edge plating.

2. Thermal Management in High-Power Exports

Problem: How does uneven heat dissipation cause solder joint fatigue in power modules?

Material Science:

| Material | Thermal Conductivity (W/m·K) | CTE (ppm/°C) |

|---|---|---|

| FR-4 | 0.3 | 14-17 |

| Aluminum Substrate | 220 | 23 |

| Ceramic (Al₂O₃) | 24 | 6.5 |

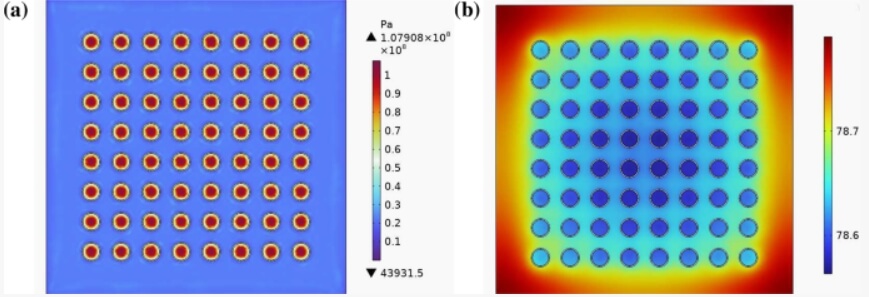

Simulation Insight:

Figure 1: Thermal stress concentration in 0.5 mm pitch BGA (Ansys Mechanical).

Design Rule:

- Via-in-Pad: Reduce thermal resistance by 40% (IPC-7093D).

- Copper Weight: Use 3 oz Cu for power layers (Rθ=1.2°C/W vs. 1 oz Cu=3.1°C/W).

3. RoHS Compliance and Material Selection

Problem: Why do halogen-free substrates (HF) increase fabrication costs by 25%?

Chemistry & Economics:

- Halogen-Free Flame Retardants: Phosphorus-based additives reduce UL94 V-0 compliance time but raise Dk from 4.0 to 4.5.

- Cost Drivers:

- Laser drilling HF materials: 0.05/holevs.FR−4:0.05/holevs.FR−4:0.03/hole.

- Lead-free solder (SAC305) reflow requires ±2°C profile control.

Regulatory Checklist:

- EU RoHS Directive: Cd <100 ppm, Pb <1000 ppm.

- China GB/T 26572: Additional Sb limit <1000 ppm.

Terminology Sidebar (Interactive Glossary)

1. HDI (High-Density Interconnect):

Microvias (<100 µm), fine traces (<75 µm), and sequential lamination.

2. CTE (Coefficient of Thermal Expansion):

Material expansion per °C; mismatch causes warpage (ΔL=α·L₀·ΔT).

3. Tg (Glass Transition Temperature):

FR-4’s Tg=130-180°C; higher Tg reduces delamination risk.

Export-Optimized Design Strategies

1. Stackup Design for Multimarket Compliance

6-Layer Example:

| Layer | Material | Thickness (mm) | Purpose |

|---|---|---|---|

| 1 | HF Prepreg | 0.10 | Signal (Impedance 50Ω) |

| 2 | 1 oz Cu | 0.035 | Ground |

| 3 | FR-4 Core | 0.20 | Power |

| 4 | 2 oz Cu | 0.070 | Thermal Path |

| 5 | Rogers 4350B | 0.08 | RF Signals |

Cost-Saving Tip: Use hybrid stackups (FR-4 + Rogers) for mixed-signal boards.

2. Humidity Control in Shipping

Moisture Sensitivity Level (MSL):

- MSL 3: 168 hours floor life at 30°C/60% RH.

- Export Packaging: Vacuum-sealed with desiccant (≤5% RH).

Failure Case:

- A German automotive OEM rejected 5,000 boards due to «popcorning» (MSL 3 parts exposed to 85% RH).

Industry Applications & Long-Tail Keywords

- Medical Devices: “ISO 13485-compliant flexible PCB exports”

- Aerospace: “MIL-PRF-31032 Class 3 rigid PCBs”

- Consumer IoT: “Halogen-free PCB for EU RoHS certification”

FAQs: Trigger Rich Snippets

Q: How to calculate moisture absorption for export packaging?

A: Use IPC/JEDEC J-STD-033B: Bake at 125°C for 24h if MSL 3 parts exceed floor life.

Q: Minimum trace spacing for 230V AC export designs?

A: Follow IPC-2221A: 1.5 mm (uncoated) or 0.8 mm (conformal coated).

Technical Validation & References

- Standards: IPC-6012 Class 3, IEC 61249-2-21 (Halogen-Free), MIL-PRF-31032.

- Research Citations:

- “Moisture-Induced Impedance Shift in 5G PCBs” (IEEE Transactions on CPMT, 2023).

- “CTE Mismatch in Pb-Free Solder Joints” (Journal of Electronic Materials, 2022).

Authority Links: