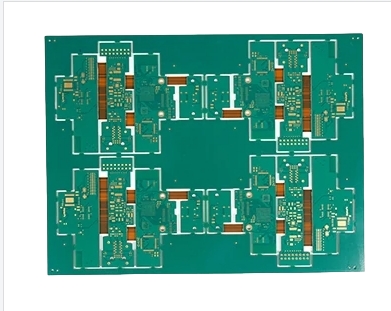

multi-layer PCB

High-end design, multi-layer PCB internal structure and experience sharing

Read MoreHXPCB is a professional one-stop PCB manufacturing and assembly service provider. We provide display PCB services, including LED PCB manufacturing and LED light PCB assembly. Our solid foundation enables us to provide free PCB proofing services (2-6 layers PCB) to our customers.

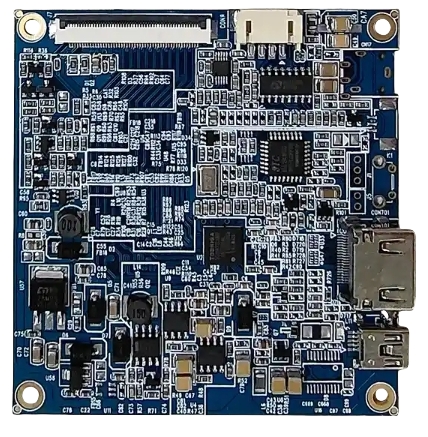

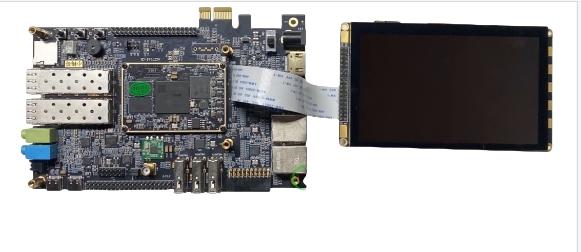

Display PCB refers to a printed circuit board used to drive, support or connect a display screen, and is an indispensable component of a display screen device. Display PCB mainly carries electronic components, provides electrical connections and signal transmission in a display screen. Depending on the type, function and application scenario of the display screen, the design and performance requirements of Display PCB will vary.

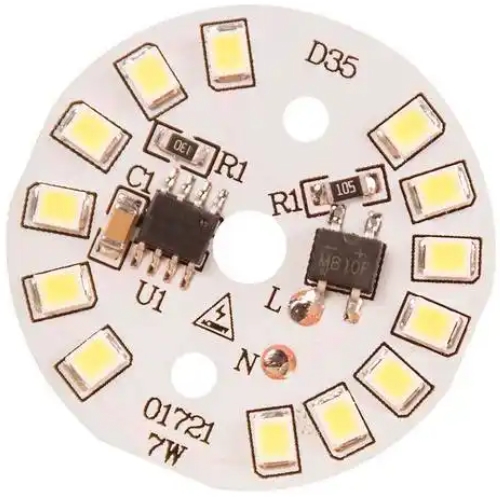

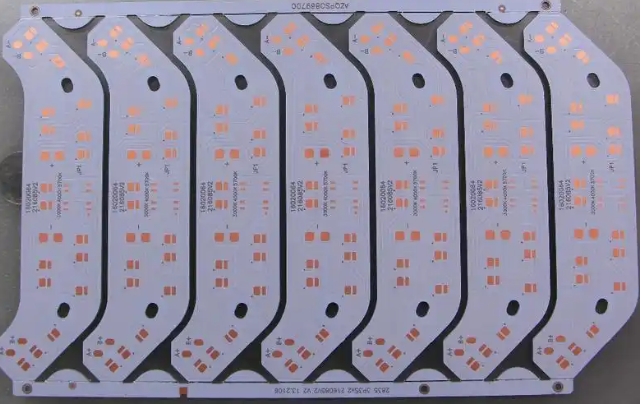

Used for LED display modules, usually with aluminum or ceramic substrates to optimize heat dissipation, used in billboards, stage backgrounds and lighting equipment, etc.

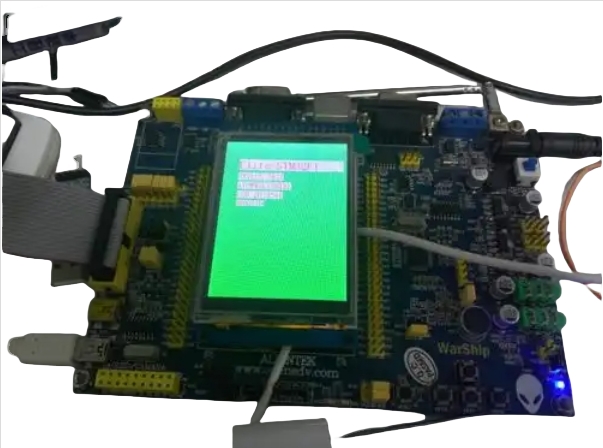

Circuit boards used for liquid crystal displays (LCDs), including driver ICs, power modules and interface circuits, commonly found in TVs, laptops, mobile phones and other devices.

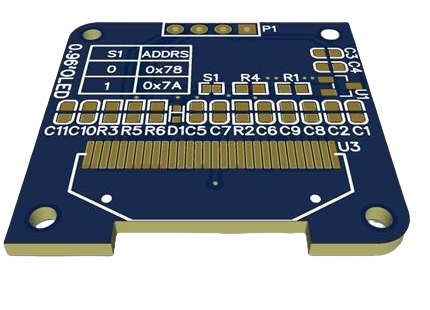

PCBs designed specifically for OLED displays, used to support high-resolution and high-refresh-rate displays, used in smartphones, smart watches and TVs, etc.

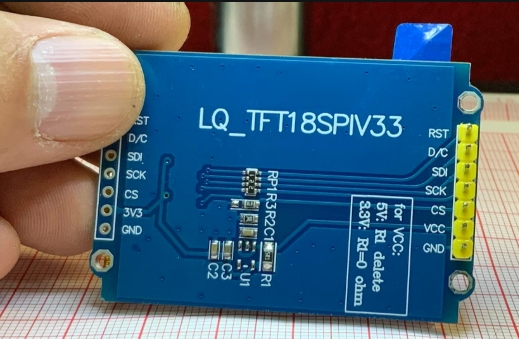

Used for TFT liquid crystal displays, mainly supporting industrial displays, vehicle displays and medical equipment.

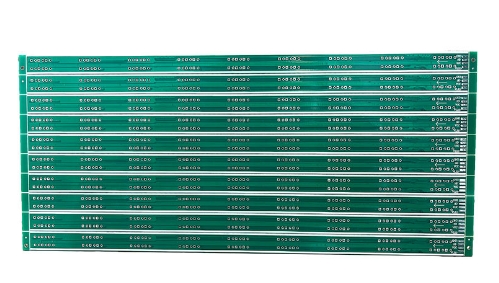

Used for display backlight modules, providing a uniform backlight source for the display to enhance the display effect.

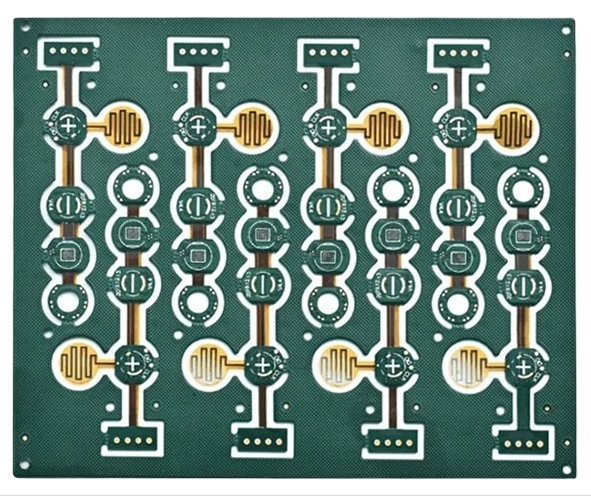

Used for stacked screens, wearable devices, and smart terminals, etc.

LED PCB (Light Emitting Diode Printed Circuit Board) is a circuit board used to integrate LEDs and their related electronic components. These boards are compact, efficient and durable and are commonly used in lighting systems, displays and automotive applications.

LEDs generate heat during operation, which can reduce their performance and lifespan if not managed properly. The PCB substrate plays a vital role in heat dissipation. Materials such as aluminum or copper are often used due to their high thermal conductivity.

LEDs generate heat during operation, which can reduce their performance and lifespan if not managed properly. The PCB substrate plays a vital role in heat dissipation. Materials such as aluminum or copper are often used due to their high thermal conductivity.

Formula for Heat Transfer:

Q=kA(T2−T1)/d

Where:

Q = Heat transfer rate (W)

k = Thermal conductivity (W/m·K)

A = Cross-sectional area (m²)

T2−T1= Temperature difference (K)

d = Thickness of the material (m)

LED PCBs must comply with EMC standards to minimize electromagnetic interference (EMI). This can be achieved through proper grounding, shielding, and trace routing.

IPC Standard Reference:

IPC-7351B provides guidance for surface mount land patterns to ensure optimal electrical performance and reduce EMI.

Compliance Standards:

IPC-6012B: Qualification and Performance Specification for Rigid Printed Boards.

IEC 62479: Safety Requirements for LED Modules.

Test Methods:

Thermal Cycling: Tests the durability of PCBs under temperature fluctuations.

Solderability Testing: Ensures that components can withstand soldering temperatures.

1. Automotive lighting(LED Light PCB Assembly)

LED PCBs are used in automotive headlights, brake lights, and interior lighting due to their high brightness and energy efficiency.

2. Medical devices(Medical LED Light PCB)

In medical applications, LED PCBs are used for diagnostic lighting and surgical lighting.

3. Consumer electronics

Smartphones, tablets, and TVs utilize LED PCBs for backlighting and display lighting.

The terms LED PCB and LED Light PCB are often used interchangeably, but they refer to different concepts within the field of LED technology and design. While both are integral to the performance of an LED system, their specific roles and design considerations can be very different.

LED PCB (Light Emitting Diode Printed Circuit Board):

LED PCB is a printed circuit board specifically designed to house and connect LEDs. The primary function of an LED PCB is to provide a stable, durable, and thermally efficient platform for mounting LEDs while ensuring efficient power distribution and heat dissipation. LED PCBs can be used in a variety of applications beyond lighting, including displays, signage, and automotive lighting.

LED Light PCB (LED Lighting PCB):

LED Light PCB refers specifically to PCBs used in lighting applications where LEDs are employed as light sources. These PCBs are designed to enable lighting systems to operate efficiently and are often customized to the requirements of a specific type of lighting, such as downlights, streetlights, or panel lights.

HXPCB provides LED PCB manufacturing and various LED Light PCB assembly services. With more than ten years of experience in electronic component procurement, it can save customers a lot of time and budget.

| Material | Type | Features | Applications |

| FR-4 | Epoxy Resin | Cost-effective, good mechanical strength | Consumer electronics, PCBs |

| Aluminum Substrate | Metal Base | High thermal conductivity | LED displays |

| Ceramic Substrate | Ceramic Base | High-temperature resistance | High-power LEDs |

| Polyimide (PI) | Flexible Material | Flexible, lightweight | Flexible circuits |

| Rogers Laminate | High-frequency | Low dielectric loss | Advanced RF applications |

| Copper Foil | Conductor | Excellent conductivity | High-resolution circuits |

| PET (Polyester Film) | Transparent Film | Flexible, lightweight | Transparent displays |

| Anisotropic Conductive Film (ACF) | Adhesive | Ensures reliable connections | LCD displays |

The manufacturing of display PCBs (printed circuit boards) is an extremely technical process that combines cutting-edge materials, precision manufacturing techniques, and a deep understanding of electrical engineering principles. This process requires rigorous attention to detail, especially given the rapid advancement of display technologies such as OLED, LCD, and LED.

Key Material Considerations:

Heat Dissipation: Due to the power demands of modern displays, especially high-resolution and high-brightness screens, display PCBs require effective heat dissipation. Materials with good thermal conductivity, such as copper and ceramic-filled substrates, are often used to enhance heat dissipation.

Dielectric Properties: For high-frequency applications, such as OLED or MicroLED, PCB materials must have low dielectric losses to maintain signal integrity at high frequencies.

PCB Design: Key Engineering Concepts

Signal Integrity and High-Speed Design

Signal integrity is critical in display PCB design. Display systems require fast data transmission for high-definition images, which is particularly challenging for large, high-refresh-rate displays.

The physical principles behind this challenge include:

Impedance Control: PCB traces need to maintain consistent impedance to avoid reflections and signal loss. This requires precise control of trace width and distance between traces. For high-speed signals, impedance needs to be controlled to ensure signal integrity, typically between 50 and 100 ohms.

Transmission Line Theory: When a signal passes through a trace on a PCB, the physical dimensions of the trace (width, length) and its distance from the reference plane affect the propagation speed and signal integrity. High-frequency signals tend to reflect at impedance discontinuities, which is why it is critical to control trace width and maintain uniform dielectric properties.

| Application Field | Description |

| Consumer Electronics | Smartphones, tablets, TVs, smartwatches. |

| Industrial Equipment | Industrial touchscreens, medical monitors, instruments. |

| Advertising & Media | LED advertising displays, digital signage, video walls. |

| Automotive & Transportation | Vehicle displays, dashboards, central control screens. |

High Precision and High Reliability:

In particular, PCBs used in devices such as OLED, LED, and LCD displays require high precision in design and assembly. These PCBs are designed to ensure reliable performance under different environmental conditions, thereby ensuring clear and consistent display output.

Compact Design:

The basic design is compact, perfectly suited for thin and light devices such as smartphones, tablets, and TVs. The miniaturization of PCBs ensures better portability without compromising functionality.

High Signal Integrity:

Display applications require high signal integrity to ensure clear images. With proper PCB design and material selection, such as high-frequency PCB materials, signal loss can be minimized, thereby improving image quality.

Advanced Materials:

Display PCBs often use advanced materials, such as flexible PCBs or high-temperature laminates, which are well suited for modern displays. These materials improve durability, reduce thermal expansion issues, and provide flexibility for flexible display technology.

Customization:

Display PCBs are highly customizable to meet the specific requirements of different display types. For example, PCBs for OLED displays require different considerations than PCBs for LCD displays. Customization optimizes performance for a variety of applications.

Complex Manufacturing Process:

The display PCB manufacturing process can be complex, especially for high-resolution displays or flexible displays. Tight tolerance requirements and the need for multiple layers or complex routing increase the complexity and cost of production.

Cost:

Advanced display PCBs, especially those used for high-end displays or specialized applications such as flexible OLEDs or high-resolution touchscreens, tend to be more expensive than standard PCBs. The use of high-quality materials and precision manufacturing techniques increases overall cost.

Thermal Management Challenges:

Display PCBs often face thermal challenges, especially in high-performance applications where heat dissipation is critical. Improper thermal management can lead to performance degradation or component failure. This requires additional design considerations, such as heat sinks or thermally conductive materials.

HXPCB provides display PCB production and assembly services, supports customized design, provides full technical support from PCB design, material selection to mass production, and provides rapid sample production and mass production capabilities to meet customers’ urgent needs.

Provide diversified production: LED PCB, LCD PCB, OLED PCB, TFT PCB, Flexible Display PCB (Flexible PCB) manufacturing solutions.

Industry experience

HXPCB has accumulated rich experience in the manufacturing of various types of display PCBs, especially in the fields of high-frequency, high-density and flexible PCBs.

technological innovation

We continue to develop advanced process technologies, such as high-heat dissipation aluminum substrates and ultra-thin flexible PCBs, to meet the market’s demand for high-performance displays. By optimizing the manufacturing process, we reduce PCB thickness and improve the thinness and lightness of display devices.

full service

HXPCB provides one-stop services from design, proofing to mass production, ensuring display PCB quality and delivery time, providing cost-effective solutions to help customers optimize costs while ensuring product performance and quality.

Display PCBs often use materials such as FR-4, aluminum substrates, ceramic substrates, polyimide (PI), and Rogers laminates to meet different thermal, electrical, and mechanical requirements.

Yes, we specialize in high-precision manufacturing, including HDI PCBs, to support high-resolution and high-frequency display requirements.

We use materials like aluminum and ceramic substrates with high thermal conductivity and design techniques to optimize heat dissipation.

The surface finish applied to a display PCB plays a key role in ensuring good solderability, durability, and protection from corrosion. Common surface finishes include:

HASL (Hot Air Solder Leveling): This process involves dipping the PCB in molten solder and then leveling it using hot air. It is a standard finish but can have issues with flatness for high-density designs.

ENIG (Electroless Nickel Immersion Gold): A more advanced finish that offers better durability, corrosion resistance, and flatness, which is important for high-density or fine-pitch components.

The choice of surface finish depends on the application and required performance characteristics.

We provide PCBs for LED, LCD, OLED, TFT, and flexible displays, customized for applications like consumer electronics, automotive, and industrial equipment.

We comply with international standards such as ISO, RoHS, and UL to ensure reliable quality and environmental compliance.

Yes, we manufacture flexible PCBs using polyimide materials, suitable for foldable, curved, and wearable devices.

Absolutely, we offer fully customized solutions and low-volume production for prototypes or specialized applications.

High-end design, multi-layer PCB internal structure and experience sharing

Read More

PCB (Printed Circuit Board) inspection is an important part of ensuring product quality, performance and reliability.

Read More

Printed circuit boards (PCBs) play a vital role in connecting and supporting various electronic components. With

Read More