multi-layer PCB

High-end design, multi-layer PCB internal structure and experience sharing

Read MoreHXPCB is a supplier engaged in the PCB industry. We provide one-stop production and assembly services for ordinary PCB, double-sided PCB, multi-layer PCB, aluminum PCB, rigid-flex PCB, HDI PCB, drone PCB and high-frequency PCB. Our production equipment and technical team enable us to have more favorable prices for our high-quality products.

HXPCB is a UAV PCB manufacturer and assembly supplier, focusing on high-quality printed circuit board PCB manufacturing and assembly. We have a technical team of more than 100 people, who can tailor manufacturing and assembly solutions according to the type of UAV the customer wants, ensuring that every customer can receive the goods from HXPCB with a pleasant mood.

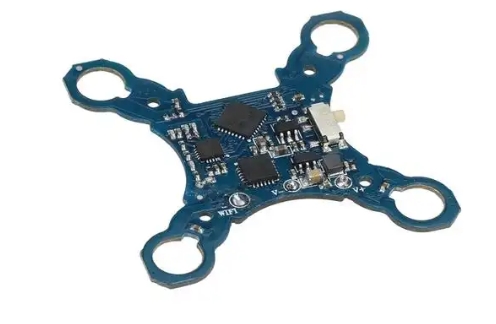

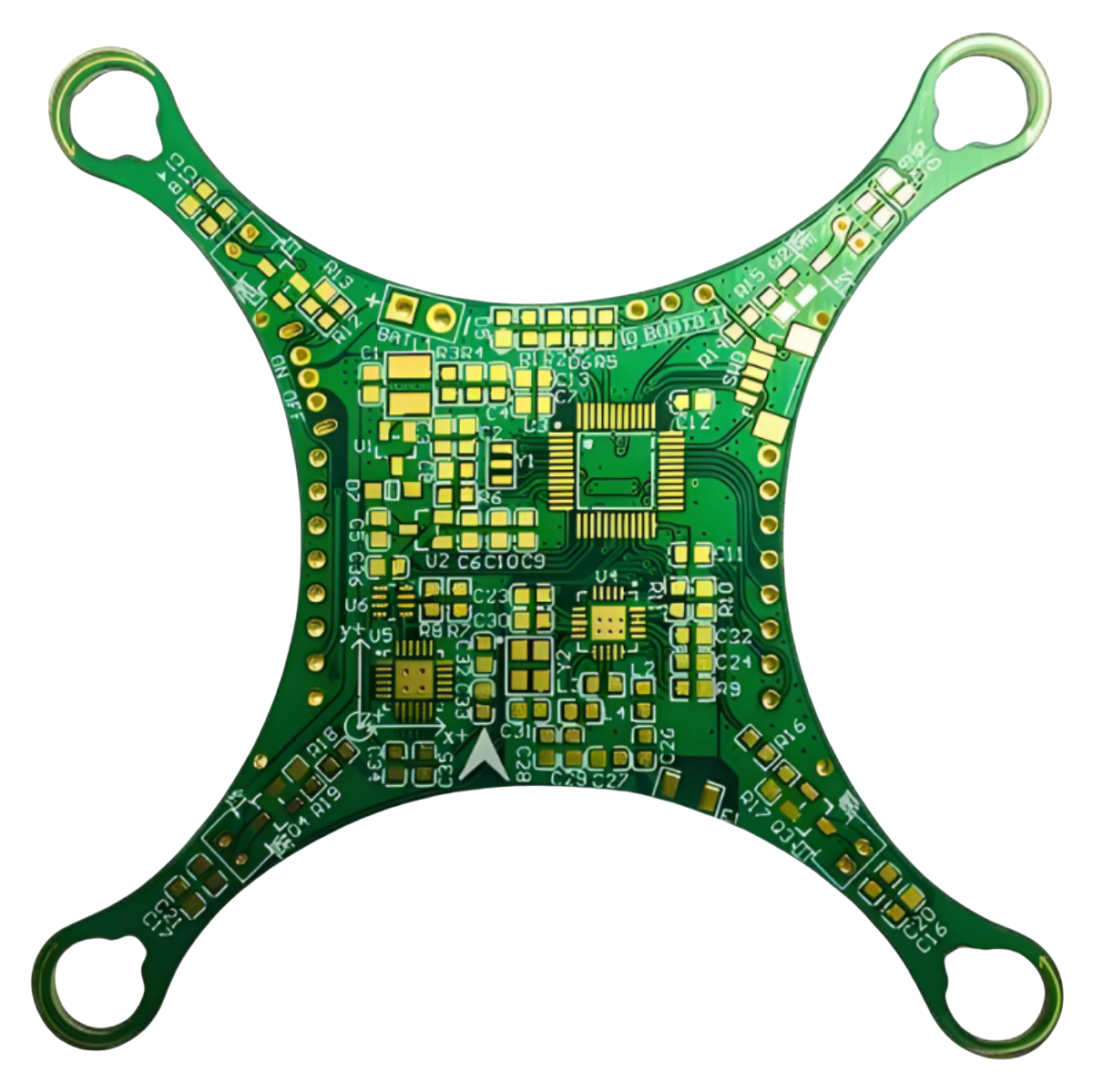

1. Lightweight design: Compared with drones and flight efficiency, the lighter the drone PCB, the higher the flight efficiency.

2. Central system: distributes and regulates the power of motors, sensors and controllers.

3. Control signal: for navigation, communication and stable transmission of signals.

4. High durability: resistant to environmental factors such as vibration, high temperature and humidity.

5. Multi-layer structure: can include 2-layer or multi-layer design of complex systems.

1. UAV PCB Solution:

«UAV PCB failure = flight risk! We focus on solving the three core problems of high-frequency signal interference, extreme temperature deformation, and vibration shedding»

2. Technical Support:

Material: RO4835 high-frequency board/FR-4 TG170 high Tg material, adapting to -40°C~150°C temperature difference

Design: 16-layer HDI blind buried hole design, impedance control ±5%

Process: immersion gold + OSP mixed surface treatment to ensure the durability of gold fingers

3. Certification system:

IPC-6012 Class 3, UL certification, compliant with EN62368 drone safety standards

Application: high-frequency image transmission/low-latency control Required technology: 20GHz high-frequency wiring, ultra-thin 0.6mm board thickness design.

Application: long endurance/anti-electromagnetic interference Required technology: 4oz thick copper power layer, EMI shielding coating.

Application: high humidity/corrosive environment Required technology: customized spraying of three-proof paint (anti-pesticide corrosion formula).

Application: extreme temperature/anti-vibration Required technology: aluminum substrate heat dissipation + rivet reinforcement process

| Application | Description |

| UAV Flight Control Board | Precision board |

| UAV Power Distribution Board | Provides reliable power delivery for motors, ESCs, and other devices |

| Motor Control Board | Electronic Speed Controller (ESC) |

| UAV Communication Module | Supports RF, GPS, Wi-Fi, and Bluetooth communication for real-time data transfer |

| UAV Battery Management System | Efficient power monitoring and management system to extend flight time |

| UAV Sensor Integration Board | Interface for cameras, GPS sensors, and obstacle detection systems |

Professional technical team: HXPCB has experienced engineers and technical teams to provide professional design, manufacturing and assembly solutions.

High quality standards: Adopt strict quality control processes, including material selection, manufacturing process and testing procedures, to ensure that each product meets international quality standards, such as IPC, ISO, etc.

Advanced equipment: Equipped with modern production equipment, including high-precision SMT placement machines, reflow machines and automatic inspection equipment to achieve efficient and high-quality production.

Fast delivery: HXPCB provides fast sample making and production capabilities, and can quickly adjust production plans according to customer needs and shorten delivery cycles.

Customized service: Provide customized PCB design and manufacturing services according to the specific needs of customers, including size, number of layers, materials and functions, etc., to ensure that customers’ special needs can be met.

High service quality: HXPCB attaches importance to customer relationships and provides high-quality after-sales service and technical support.

One-stop solution: HXPCB provides a full range of services from PCB design, material procurement, manufacturing, assembly to testing.

With the development of science and technology, drones are becoming more and more important in our daily lives. You can use them to take aerial photos of the earth, or record happy moments. You can also use them to explore and become an adventurer. You can also use them to water crops. In life, drones bring us a lot of convenience. Not only that, they are also indispensable in the military. If you are engaged in the production of drones, then buying our solutions from us is your best choice, because we are at the top of the industry in terms of product quality and service enthusiasm. HXPCB only does one thing, which is to make every customer smile with satisfaction.

High-end design, multi-layer PCB internal structure and experience sharing

Read More

PCB (Printed Circuit Board) inspection is an important part of ensuring product quality, performance and reliability.

Read More

Printed circuit boards (PCBs) play a vital role in connecting and supporting various electronic components. With

Read More