Discussion on the relationship between display PCB and LED PCB

Overview

A Display PCB (Printed Circuit Board) is a critical component that connects and controls the display screen, while LEDs (Light Emitting Diodes) are the most commonly used light sources in displays. The relationship between these two components is integral, as they jointly determine the performance and display quality of the system. This article delves into the relationship between Display PCBs and LEDs, exploring their physical principles, technical parameters, and real-world applications.

1. 显示器 PCB 的物理原理

1.1 Basic Structure of Display PCBs

A printed circuit board specifically used to connect and control the various components of a display. Its main functions include:

- Signal Transmission: Transferring image signals from the controller to the display.

- Power Management: Providing a stable power supply to the display.

- Control Logic: Implementing display control functions through embedded chips or dedicated ICs.

1.2 Physical Principles

Its operation is based on electromagnetic theory and signal integrity. The key physical principles include:

- Electromagnetic Induction: Signals transmitted through wires generate electromagnetic fields, ensuring stable signal transmission.

- Signal Integrity: Controlled through impedance matching and signal trace layout. According to the IPC-2251 standard, the characteristic impedance of signal lines is typically 50Ω or 75Ω.

1.3 Key Technical Formula

Signal integrity is critical when designing. The following formula calculates the characteristic impedance of a signal line:

Z0=138εr⋅ln(w+2hw)Z0=εr138⋅ln(ww+2h)

Where:

- Z0: Characteristic impedance (unit: Ω)

- εr: Dielectric constant

- w: Signal line width

- h: Dielectric thickness

2. Working Principle of LEDs

2.1 Basic Structure of LEDs

An LED is a semiconductor device that emits light when an electric current passes through it. Its basic structure includes:

- PN Junction: Comprising P-type and N-type semiconductors.

- Light-Emitting Layer: Where electron-hole recombination occurs, releasing energy and producing light.

2.2 Physical Principles

The operation of an LED is based on the electroluminescence effect in semiconductors. When an electric current flows through the PN junction, electrons and holes recombine, releasing photons. The wavelength (color) of the emitted light is determined by the bandgap of the semiconductor material.

2.3 Key Technical Formula

The luminous intensity of an LED can be calculated using the following formula:

L=η⋅I⋅q⋅νL=η⋅I⋅q⋅ν

Where:

- L: Luminous intensity (unit: cd)

- η: Quantum efficiency

- I: Current (unit: A)

- q: Elementary charge (unit: C)

- ν: Emission frequency (unit: Hz)

3. Relationship Between Display PCBs and LEDs

3.1 Functional Relationship

显示屏 PCB 的主要功能是驱动和控制 LED。通过 PCB 上的驱动芯片,LED 可以执行以下功能:

- On/Off Control: Turning LEDs on or off based on signals.

- Brightness Adjustment: Adjusting LED brightness using PWM (Pulse Width Modulation).

- Color Mixing: Achieving color mixing by controlling the current ratio of RGB LEDs.

3.2 Structural Relationship

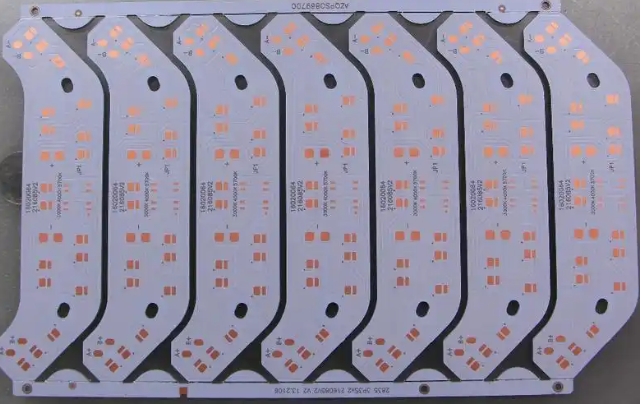

Display PCBs and LEDs are connected in the following ways:

- SMD LEDs: Directly soldered onto the surface of the PCB.

- COB LEDs: Packaged at the chip level and mounted directly on the PCB.

- LED Strips: Connected to the PCB through connectors or wires.

3.3 Technical Comparison

sheet

| Parameter | Display PCB | LED |

|---|---|---|

| Function | Signal transmission, power management, control logic | Light emission, display images |

| Physical Principle | Electromagnetism, signal integrity | Semiconductor electroluminescence |

| Process Parameters | Layer count, impedance matching, signal integrity | Quantum efficiency, emission wavelength |

| Typical Applications | Displays, touchscreens | Backlighting, indicators, decorative lighting |

4. Collaborative Design of Display PCBs and LEDs

4.1 Signal Integrity Design

In high-resolution displays, signal integrity is critical. Optimization can be achieved through:

- Impedance Matching: Ensuring signal line characteristic impedance is 50Ω.

- Decoupling Capacitors: Placing decoupling capacitors on the PCB to filter high-frequency noise.

4.2 Thermal Management

LEDs generate heat during operation, so thermal management is essential:

- Heat Sink Design: Adding heat sinks on the PCB for heat dissipation.

- Cooling Solutions: Using heat sinks or fans to reduce temperature.

4.3 Optical Design

The optical performance of LEDs directly impacts display quality. Optimization can be achieved through:

- Reflector Design: Adding reflectors around LEDs to improve light efficiency.

- Diffusers: Using diffusers to uniform light distribution and reduce glare.

5. Industry Application Cases

5.1 Display Screens

- LCD Screens: Display PCBs control LED backlights to achieve high brightness and high contrast ratios.

- OLED Screens: Display PCBs control OLED pixels to achieve high refresh rates and accurate color reproduction.

5.2 Automotive Electronics

- Instrument Clusters: Combining Display PCBs and LED PCBs for high-reliability and long-lifetime display systems.

- Interior Lighting: Implementing adjustable color and brightness lighting systems using LEDs and Display PCBs.

5.3 Industrial Control

- Touchscreens: Combining Display PCBs and LED PCBs for high-precision and durable industrial control interfaces.

6. Technical Data and Formulas

6.1 Display PCB Technical Parameters

sheet

| Parameter | Unit | Typical Value |

|---|---|---|

| Signal Line Impedance | Ω | 50 |

| Operating Frequency | MHz | 100-500 |

| Power Supply Voltage | V | 3.3/5.0 |

6.2 LED Technical Parameters

sheet

| Parameter | Unit | Typical Value |

|---|---|---|

| Emission Wavelength | nm | 400-700 |

| Luminous Intensity | cd | 100-1000 |

| Quantum Efficiency | % | 50-90 |

6.3 Conversion Table

The following is the relationship between LED luminous intensity and current:

L=η⋅I⋅q⋅νL=η⋅I⋅q⋅ν

By adjusting the current I and frequency ν, precise control of the luminous intensity L can be achieved.

7. Conclusion

Display PCB and LED PCB are two core components in the display system. The relationship between the two is rooted in electromagnetic theory, semiconductor physics and optical principles. By optimizing the signal integrity of the display PCB and the optical performance of the LEDs, a high-performance and high-reliability display system can be achieved. This article comprehensively analyzes the relationship between the two through formulas, technical parameters and application cases. If there is any error, please point it out and correct it in time.