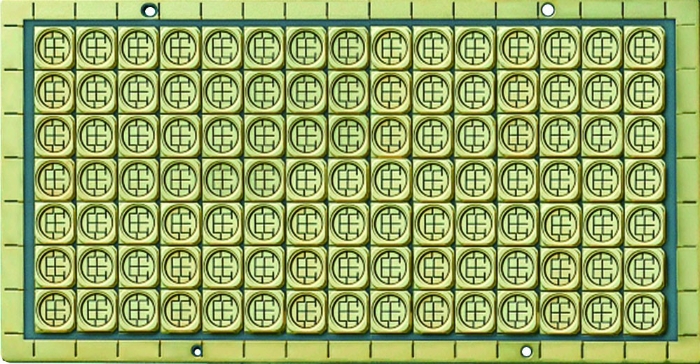

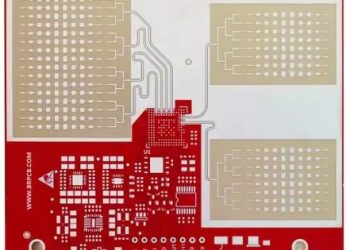

multi-layer PCB

High-end design,

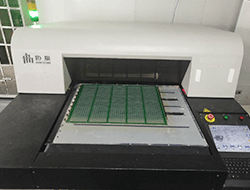

Read MoreHuaxin focuses on the research and development of ceramic PCBs, extra-large size circuit boards, multi-layer circuit boards, metal substrates, rigid-flex high-frequency circuit boards, HDI circuit boards and related processes, providing a full range of services from PCB design, proofing, processing, assembly, etc.

.jpg)

Ceramic PCB is a printed circuit board that uses ceramic material as the substrate. Compared with traditional FR4 or metal substrate PCB, ceramic PCB has excellent thermal conductivity, mechanical strength and high temperature stability, and is widely evaluated in electronic products that require higher performance, especially in high power, high frequency and high temperature environments.

The thermal conductivity of ceramic materials is usually times higher than that of metal and traditional FR4 materials, and they can work more efficiently.

Ceramic PCBs have lower dielectric constants and lower electrical losses, and perform extremely well in high-frequency and RF applications.

Ceramic PCBs can operate at higher operating temperatures, usually able to withstand temperatures above 300°C, while the upper temperature limit of ordinary FR4 materials is about 130°C.

Ceramic materials themselves have high mechanical strength and impact resistance, and can withstand greater physical stress.

Ceramic PCBs have very good dimensional stability when the temperature changes, especially suitable for applications that require precise dimensional control.

Ceramic PCB materials have low dielectric constants and dissipation factors, making them ideal for high-frequency circuits and radio frequency (RF) applications.

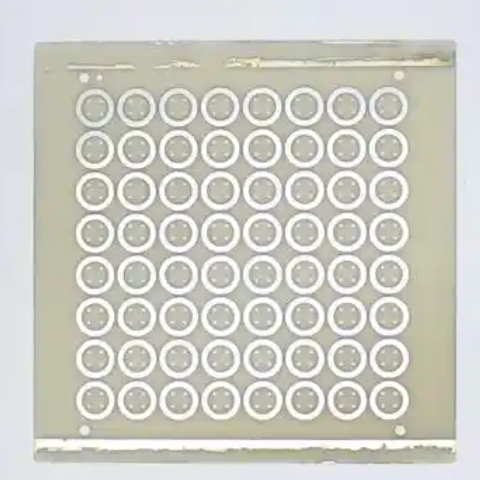

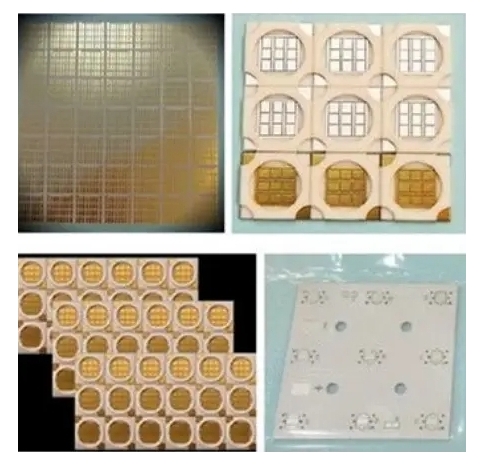

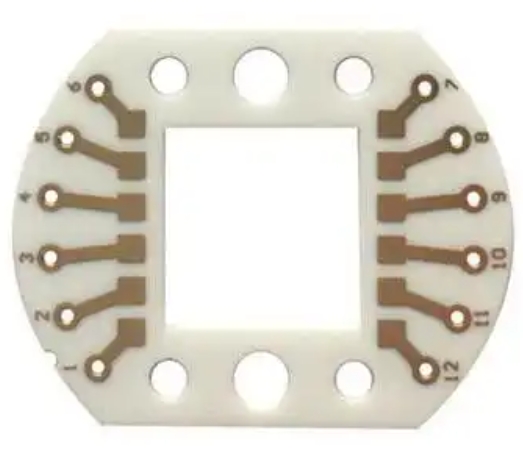

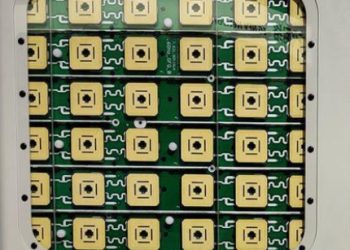

The circuit is arranged on one side of the ceramic substrate. It is usually used for simple circuit design and is common in applications such as low-power LED lighting and sensors.

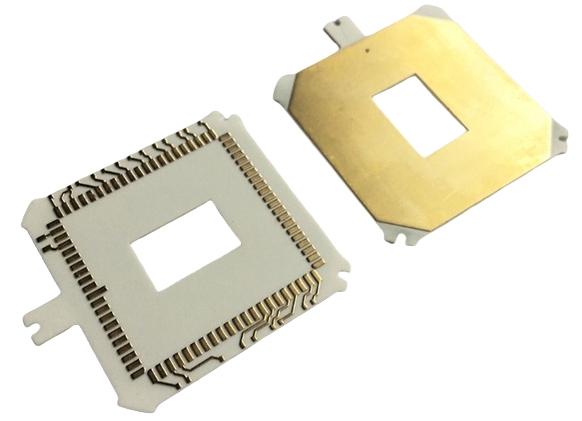

Arranging circuits on both sides of the ceramic substrate is suitable for more complex circuit designs, which can improve the integration of components and save space.

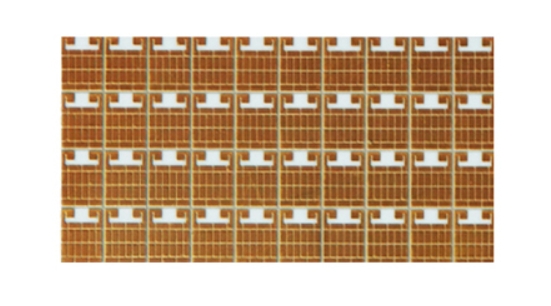

It consists of a multi-layer ceramic substrate with each layer connected by a highly conductive metal layer. This design is suitable for high-density, high-frequency and high-power applications.

Substrate preparation

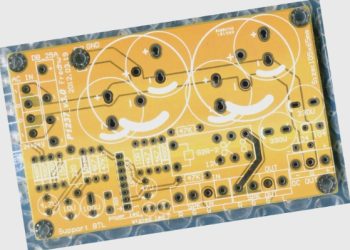

The substrate of ceramic PCB usually adopts ceramic materials such as aluminum oxide (Al2O3), aluminum nitride (AlN), silicon nitride (SiN). The preliminary process includes cutting the ceramic material into the required size and shape.

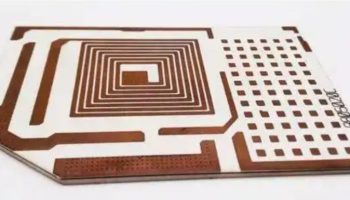

Circuit pattern transfer

A layer of photoresist is applied to the surface of the ceramic substrate, and then the circuit pattern is transferred to the photoresist by ultraviolet light irradiation. Then it is developed to leave the graphics of the circuit pattern, and then according to the design requirements, holes are punched on the ceramic substrate to form the necessary electrical connection channels.

Electrode deposition

Conductive metals (such as gold, silver, copper, etc.) are deposited on the surface of the ceramic substrate through evaporation, sputtering or chemical vapor deposition (CVD) and then the metal layer is thickened by electroplating to ensure the conductivity of the circuit.

Sintering process

After the metal deposition is completed on the ceramic substrate, sintering treatment is required to ensure good bonding between the metal and the ceramic substrate.

Surface treatment

After the circuit pattern and metal deposition are completed, the ceramic PCB is surface treated, such as tin plating, gold plating, etc., to improve weldability and reliability.

The equipment costs of ceramic materials and special processes (such as laser processing, DPC, LTCC) are high, resulting in a significant increase in overall manufacturing costs compared with traditional PCBs.

Precision pattern transfer

Ceramic substrates require high-precision circuit patterns, and the ceramic surface is hard and irregular, which increases the complexity of processes such as photolithography and laser marking.

Ceramic materials (such as aluminum oxide, aluminum nitride, silicon nitride) have high hardness and brittleness, and are prone to cracks and fragments during processing, making manufacturing more difficult.

The bonding strength between the ceramic substrate and the metal layer (such as copper, silver) is difficult to ensure, especially in high temperature or high humidity environments, which is prone to delamination or peeling.

Although ceramic materials have low dielectric loss, material purity and surface quality still need to be strictly controlled in high-frequency applications to reduce signal loss and reflection.

Ceramic materials have high hardness, and micro-hole processing (such as through holes or blind holes) can easily cause chipping or processing deviations.

Ceramic PCB:

1. Substrate material: ceramic (usually alumina or alumina ceramic).

Advantages: good thermal and electrical conductivity, suitable for high frequency, high temperature and high power applications.

Disadvantages: high cost, difficult processing, thickness is usually limited.

2. More reliable in high temperature and high frequency environments, suitable for mission-critical applications.

FR4 PCB:

1. Substrate material: epoxy resin composite material (FR4).

Advantages: low cost, high mechanical strength, easy processing, suitable for mass production.

Disadvantages: poor thermal and electrical conductivity, large high-frequency signal attenuation, poor performance stability at high temperature.

2. Reliable in ordinary environments, but may cause signal attenuation or deformation at high temperature or high frequency

Ceramic PCB:

1. High cost, especially in small batch production, the price difference is obvious.

2. Ceramic is hard and difficult to process, and it is easy to damage processing tools such as drills.

3. The thickness is usually between 0.25mm and 1.5mm, and thicker ceramic substrates are difficult to produce.

FR4 PCB:

1. Low cost, it is the most commonly used PCB material on the market.

2. Wide thickness range (0.2mm~3.0mm), flexible processing.

3. However, high-frequency signals may cause greater losses.

🔌 5G base station aluminum nitride RF power amplifier module

🔌 Satellite communication T/R component substrate

🔌 Millimeter wave radar antenna array

🚗 Electric vehicle battery management system (BMS).

🚗 On-board laser radar control board.

🚗 Electric drive system silicon carbide power module.

🏭 Advanced driver assistance systems (ADAS) such as cruise control.

🏭 blind spot detection.

🏭 and traction maintenance.

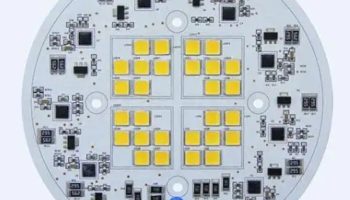

💡 LED street lights.

💡 car headlights.

💡 projector light sources.

🔌5G communication equipment.

🔌5G base stations and RF modules.

🔌 filters, 🔌amplifiers.

🔌antenna arrays and other RF components.

✈️Radar systems.

✈️satellite communication equipment.

✈️high-frequency radio frequency identification (RFID), etc.

| Parameter | Typical Value/Range |

| Base Material | Al₂O₃ (Alumina) |

| Thermal Conductivity | Aluminum (Al) |

| Dielectric Constant (Dk) | Al₂O₃: 9.8, AlN: 8.6, Si₃N₄: 7.8 |

| Dielectric Loss (Df) | Al₂O₃: 0.001, AlN: 0.0005 |

| Coefficient of Thermal Expansion (CTE) | Al₂O₃: ~7 ppm/°C, AlN: ~4 ppm/°C, Si₃N₄: ~3 ppm/°C |

| Substrate Thickness | 0.25 mm – 1.5 mm |

| Metal Layer Thickness | 10 µm – 500 µm |

| Working Temperature | -55°C to 850°C |

| Breakdown Voltage | >15 kV/mm |

| Surface Finish | ENIG, Silver, Gold |

| Metal Adhesion Strength | >10 N/mm |

HXPCB provides high-performance ceramic PCB integration services that meet the needs of high-power, high-frequency, and high-reliability applications. These include ceramic circuit board solutions in multiple fields such as LED lighting, 5G communications, automotive radar, medical equipment, etc. HXPCB focuses on precision manufacturing and reliable PCB assembly processes to ensure the excellent performance and stability of our assembled PCBs in various extreme environments.

The quality of ceramic PCBs starts with the materials used. Upon receipt of the raw ceramic substrate, we conduct a thorough inspection to verify that it meets the specified technical standards. This includes checking the material composition, thickness, and surface condition to ensure consistency and reliability throughout the manufacturing process.

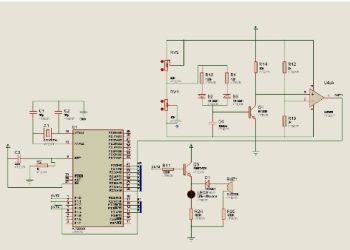

Before production begins, our experienced engineers conduct a comprehensive review of the PCB design. We analyze the Design for Manufacturability (DFM) to identify any potential issues that may affect production quality or the final performance of the PCB.

Once the ceramic PCB is assembled, we conduct multiple tests to verify the integrity and quality of soldering and component placement. Our team uses advanced technologies such as Automated Optical Inspection (AOI) and X-ray Inspection to ensure that all components are properly placed without solder bridges or misalignment.

Each ceramic PCB is electrically tested to confirm that all electrical connections are functional and within specified tolerances. We perform In-Circuit Testing (ICT) and functional testing to verify the electrical integrity of the board.

Subject ceramic PCBs to temperature variations from -40°C to 150°C to ensure they maintain structural integrity and functionality under extreme temperatures. Perform physical force tests such as simulated vibration, shock, and bending to verify its physical resistance and functionality.

We perform precise dimensional measurements to ensure that each ceramic PCB meets the required specifications. Visual inspections are performed at each stage of production to detect any cosmetic defects such as scratches, cracks, or surface inconsistencies. After all tests are completed, a final inspection is performed to verify that the entire production process meets all quality standards.

Yes, ceramic circuit boards can operate at temperatures up to 300°C due to the inherent heat resistance of ceramic materials such as AlN and Si₃N₄.

Typical thicknesses for ceramic printed circuit boards (PCBs) range from 0.25 mm to 3.0 mm. The thickness selection depends on the application needs, the type of ceramic material, and the design requirements.

Because it has high thermal conductivity, which enables efficient heat dissipation, which is critical in high-power applications. Its low thermal expansion and excellent electrical insulation ensure stability and reliability under extreme conditions.

Ceramic PCBs typically use aluminum oxide (Al₂O₃), aluminum nitride (AlN), and silicon nitride(SiO₂) as the substrate materials. Each material offers unique thermal and dielectric properties:

Al₂O₃: Affordable and widely used, with moderate thermal conductivity.

AlN: High thermal conductivity and good electrical insulation.

SiO₂: Excellent mechanical strength and thermal stability.

Yes, HXPCB is a one-stop PCB manufacturing and PCB assembly service provider. We have our own independent manufacturing plant. We support small batch to large batch orders. Both our salesmen and our technical team will do their best to solve your problems.

LED lighting: High-power LEDs, automotive lighting.

5G and RF communications: Filters, amplifiers, antennas.

Automotive electronics: ADAS, radar systems, power control units.

Medical devices: Implantable devices, high-precision diagnostic equipment.

Aerospace: Satellites, avionics.

Yes, ceramic printed circuit boards (PCBs) are well suited for high-frequency applications due to their low dielectric constant (Dk) and dielectric loss (Df), ensuring minimal signal distortion and loss.

Thermal conductivity: Ceramic boards dissipate heat much better than FR4.

Operating temperature: Ceramics can withstand higher temperatures.

Electrical properties: Ceramic boards have low dielectric losses, making them ideal for high-frequency applications.

However, ceramic boards are generally more expensive and more difficult to process.